WHAT ARE CUSTOM ENGINEERED PROCESS SKIDS FOR OIL, GAS, AND INDUSTRIAL APPLICATIONS?

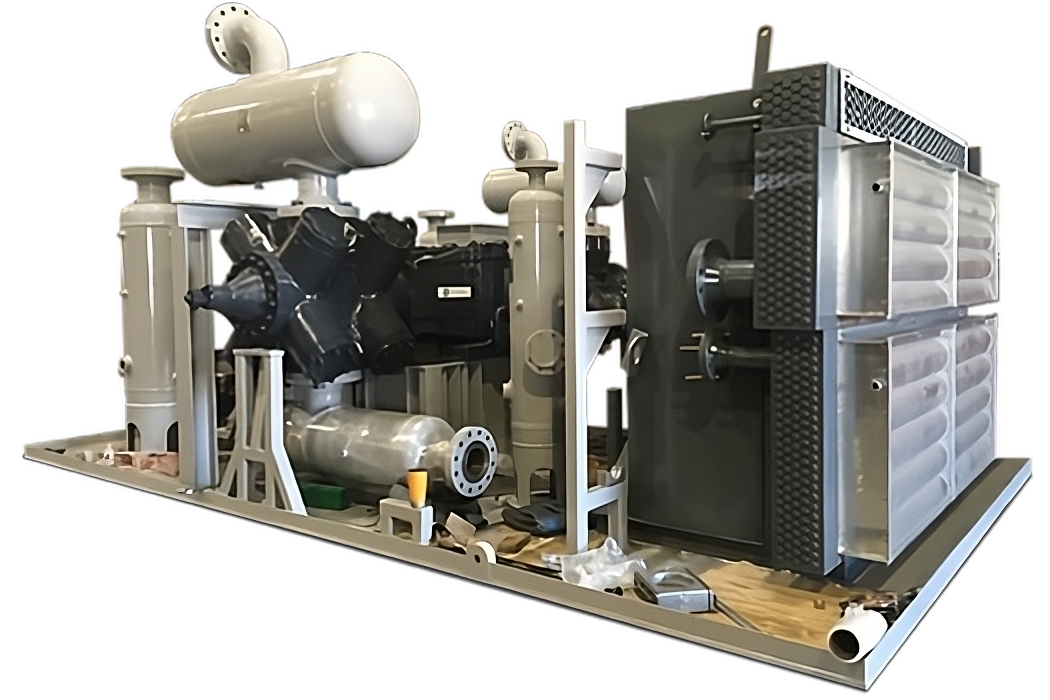

Custom Engineered Process Skids for oil, gas, and industrial applications refer to bespoke, modular systems designed to streamline various process operations within these sectors. These skids typically integrate multiple process components, such as piping, valves, instrumentation, and control panels, onto a compact, transportable frame or platform.

The engineering process behind these skids involves a meticulous design phase where systems are tailored to meet the precise performance specifications set forth by the client. This customization can range from simple assembly configurations to complex, integrated process solutions, encompassing mechanical and electrical components, control systems, and advanced automation technologies.

Oil and gas, power, chemical, marine, and industrial companies have come to know HVM as a provider of outstanding process skids.

Modular process skids have revolutionized the way industries such as oil and gas, chemical plants, and food and beverage manufacturing approach the construction and integration of process systems. A process skid is essentially a processing system built into a frame that allows for easy transportation and integration into existing operations, offering a "system in a box" solution that enhances project timelines and operational efficiency.

Fabricating these individual skids or multiple skids in a controlled shop environment enables skid manufacturers to leverage engineering and design costs, fabricate multiple replicas, and ensure high-quality assembly with advanced tools like orbital welders. This method of parallel construction not only shortens the project schedule but also minimizes disruptions to ongoing operations, allowing for facility upgrades or the addition of new process applications without significant downtime.

In oil and gas sectors, modular process skid systems are pivotal for applications ranging from fuel gas treatment to power generation skids. These skids can be combined or used as standalone units, offering flexible solutions for pilot plants or full-scale operations. The food industry benefits from modular skids in processes such as flavor mixing and batch mixing, where precision and hygiene are paramount.

For construction projects, the advantages of modular process skids include reduced project completion times and the potential for delayed differentiation, allowing for customization at later stages of the project. This approach contrasts traditional construction methods, offering significant rollout savings and reducing the environmental impact of construction.

Heat recovery, solvent recovery, and fuel delivery systems are examples of how modular skids support sustainable and efficient industrial processes. The concept of "fabricating skids in a controlled" environment also applies to complex systems like centrifuge systems and chemical processing units, where precision and safety are critical.

Modular process skid packages represent a shift towards more agile and cost-effective solutions in industrial construction and process system design. By adopting these modular systems, companies can achieve faster project completion, enhance the reliability of their process equipment, and benefit from the scalability of adding or modifying skids according to the evolving needs of their operations.